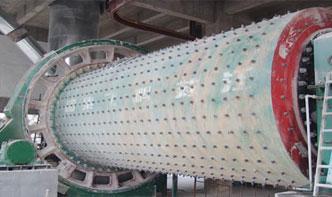

Nickel slag production line/chaeng nickel slag pant/nickel slag mill

18/01/2019 · The fine nickel fire smelting slag is mixed with water glass to produce high strength, waterproof and sulfate resistant cementitious materials. The water quenched nickel slag can be used to make bricks and prepare fire resistant (800 °C) concrete. Product advantages 1, large vertical roller mill to support