Linear Vibratory Feeders Principles

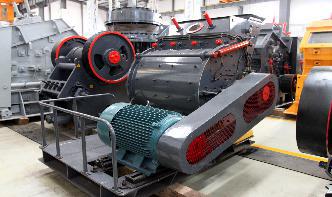

HomeSolutions linear vibratory feeders principles 150tph andesite crushing and reshaping production line Material andesite Output size mm Capacity 150tph linear vibratory fe. Turnkey Project EPC Scheme. Vibratory Feeder Working Principle ...