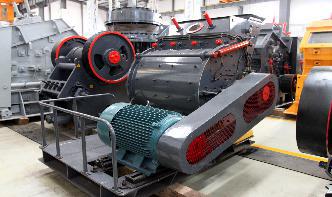

Sand And Gravel Processing

11/95 Sand And Gravel Processing Sand And Gravel Processing Process Description16 Deposits of sand and gravel, the unconsolidated granular materials resulting from the natural disintegration of rock or stone, are generally found in nearsurface alluvial deposits and in subterranean and subaqueous beds.