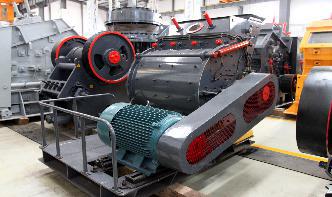

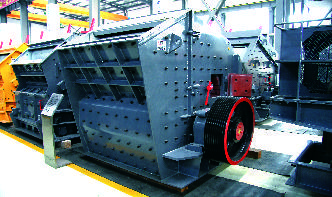

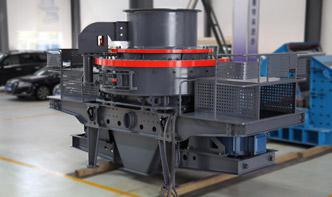

A study of operating parameters of a roller mill with a new .

· These have a positive effect on increasing performance, reducing power consumption and unit energy consumption, and eliminating wear of large structural elements of the mill, improving the economic and environmental characteristics of the processing of grainy materials. REFERENCES 1. W.